Drake T-4X & R-4A currently in the K4MSG ham shack

Before getting into my most recent Drake equipment acquisition and repair, a few comments about owning and operating older vacuum-tube radio equipment are in order for those who have never tried it. The guidelines that follow are not meant to discourage collection, repair, restoration and operation of this gear but rather to point out some of the possible pitfalls and areas of frustration that may prove discouraging to the unsuspecting neophyte. |

GUIDELINES TO BOATANCHOR OWNERSHIP

1. THERE IS NOT ALWAYS "INSTANT GRATIFICATION" WHEN TRYING TO PUT DECADES-OLD VACUUM-TUBE RADIO EQUIPMENT ON THE AIR.

In this age of "instant gratification" it is folly to expect that every piece of older, tube-type radio gear is going to be ready for "on the air" use without some kind of TLC by its latest owner. Unless an item has been fully restored by a previous owner, with aging components (especially electrolytic capacitors) replaced, switches and pots cleaned, and alignment performed, the equipment may work marginally at best and may not even work at all. In addition, attempting to use the equipment WITHOUT such maintenance can, in the worst cases, result in catastrophic failure of some old components (such as the aforesaid electrolytic capacitors) and subsequent destruction of near-irreplaceable parts like transformers. In such a case, a piece of otherwise nice-looking vintage equipment, purchased perhaps at a cost of a few hundred dollars (and sometimes more!) becomes little more than a "parts rig" - or a pricey doorstop.

2. VACUUM-TUBE EQUIPMENT USES OPERATING VOLTAGES THAT ARE LETHAL.

Nowadays we are conditioned to equipment that operates from a 12 volt DC power source, commonly from the ubiquitous 13.6-volt DC power supply. Vacuum tube equipment, however - even receivers - can use operating voltages of hundreds of volts and in the case of transmitting equipment up to 1,000 volts or even more. Anything less than extreme caution when probing the innards of this equipment is - literally - taking your life in your hands.

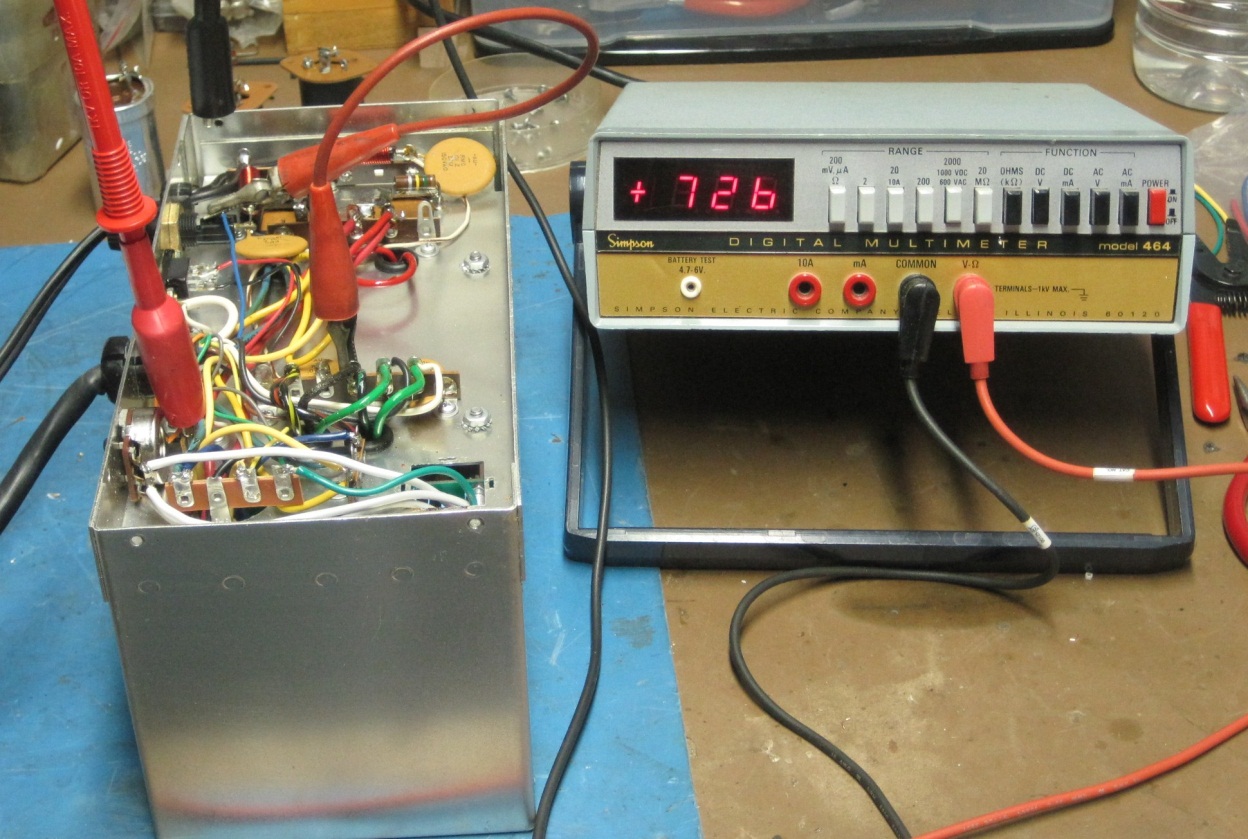

3. IF YOU DON'T HAVE TEST EQUIPMENT YOU WILL BE LIMITED IN WHAT YOU CAN ACCOMPLISH AND YOU MAY HAVE TO PAY SOMEONE ELSE TO DO THE WORK.

If you want to restore vintage radio gear you will either need some test equipment or you will need extra cash - possibly a LOT of extra cash. The two approaches are to do it yourself or pay someone else to do it, with the latter being the most expensive UNLESS you are faced with having to spend a fair amount of money to procure test gear in order to try the first approach. At a minimum you will need a good VOM (preferably a high-impedance digital voltmeter or VTVM), some sort of RF signal generator, a wattmeter and a dummy load. An oscilloscope and frequency counter are valuable additions and are worth the extra cost if you do much troubleshooting and alignment.

I personally prefer doing the work myself because that's part of the fun of owning vintage gear and I have over 40 years of experience as an electronics professional, but that isn't for everyone. And whichever approach you take, understand and evaluate the potential costs before you jump in too deeply.

4. THERE IS A DIFFERENCE BETWEEN "REPAIR" AND "RESTORATION."

One of the decisions that the new owner of a piece of vintage equipment must make is whether to simply repair and update the equipment to make it functional, or to embark on a full-blown restoration and attempt to make it "new" again. If you're really into collecting and want as near-perfect examples as possible you can take the latter course, but bear in mind that this can be a very time-consuming and expensive proposition. Merely "cleaning it up" and making it functional can generally be done much more quickly and inexpensively and will allow you to enjoy operating the equipment sooner. The choice is yours.

5. VINTAGE AMATEUR EQUIPMENT WILL NEVER EQUAL THE OPERATING CONVENIENCE, PERFORMANCE AND ERGONOMIC FEATURES OF MODERN RADIO EQUIPMENT.

As neat as it is to play with older equipment, in a fast-paced contest or under marginal or crowded conditions vintage vacuum-tube equipment cannot keep up with the convenience & efficiency of a modern transceiver. That doesn't mean it isn't fun to use the old gear, and sometimes it can even pleasantly surprise you with how well it actually does work, but in the final analysis modern equipment is just better and easier to use.

PART II: DRAKE RADIO REPAIR & OPERATION

With the above guidelines in mind, let's take a journey through the repair and operation of some vintage vacuum-tube Drake radio equipment. While every brand has its own idiosyncrasies and the problems encountered can vary from simple to complex, what follows will at least give a flavor of what it can be like to spend time tinkering with vintage gear.

|

1. THE DRAKE 2B |

Drake 2B Receiver s/n 2052

A solid, dependable receiver that works very well when paired with a Drake 2NT or just about any other vintage CW transmitter, e.g. Johnson Viking, Heath, Eico, etc. |

The R-4 series began life in 1964 and I owned one of the first R-4s, serial #727 (which I should have kept but sold in 1979). One of the key features of this receiver is the use of a linear, permeability-tuned local oscillator that provides fairly good dial calibration to the nearest kilohertz and can be "guesstimated" closer than that. Many Drake aficionados prefer the later R-4B and R-4C versions but I've always liked the R-4A, having owned a couple of them in the past.

The R-4A has a few upgrades & improvements over the original R-4 and was built in two versions, an early 13-tube model and later an 11-tube version with transistor circuitry taking the place of two of the tubes. Either version works fine and both have that "tube" sound to the audio output that is so dear to we old-timers.

Somehow I ended up with THREE Drake R-4A receivers, two 13-tube versions and one 11-tube version. The following describes what I bought.

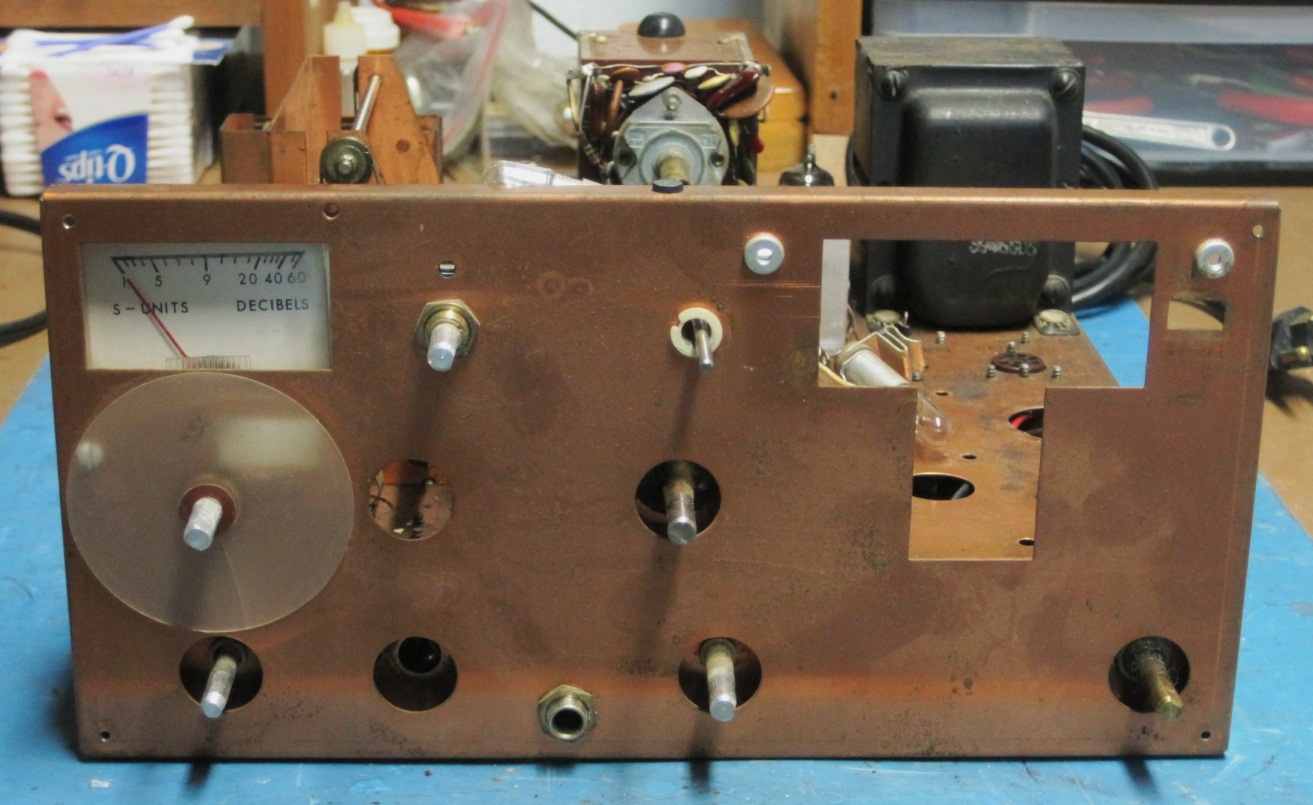

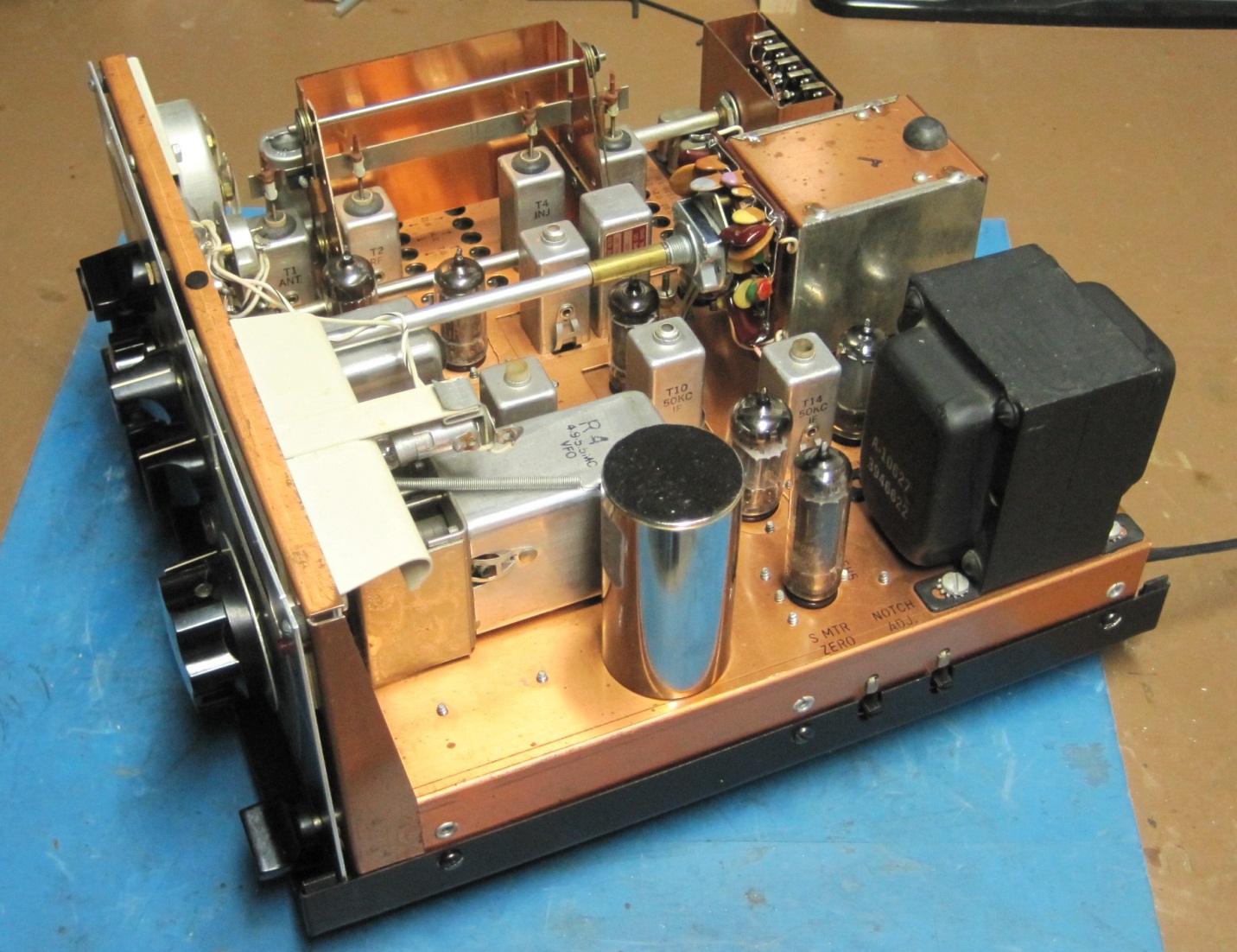

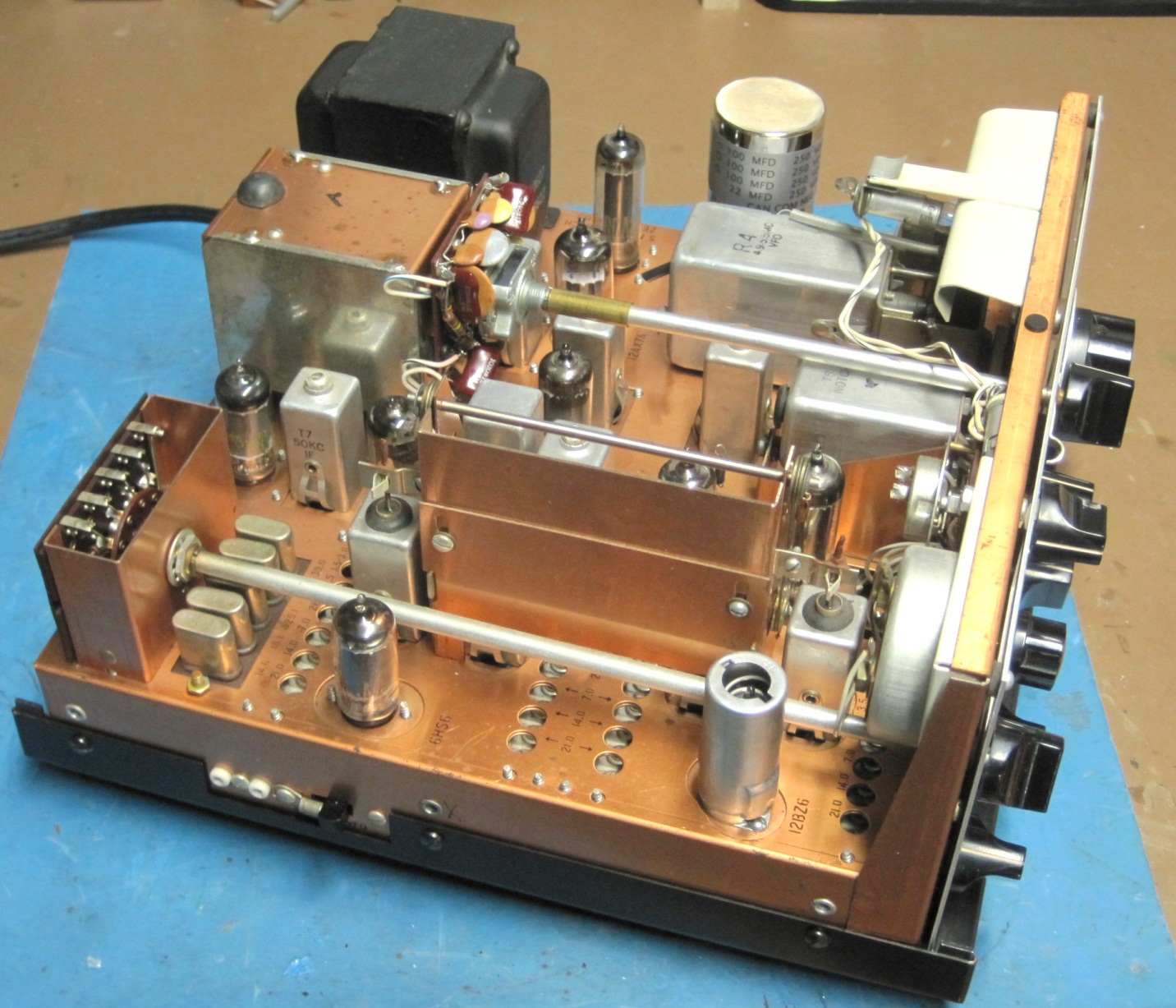

R-4A #3735: Although in working condition, this unit has a number of problems. The copper chassis is quite discolored and pitted, the electrolytic "can" capacitor was "jerry-rigged" with discrete electrolytics in a slip-shod "re-capping" effort, and the preselector exhibited slippage due to wear on the inner drive shaft. Since this unit requires extensive repair work before being fully serviceable it was decided to look around for another one and to save #3735 as a "winter project." The photos and attached descriptions illustrate some of the issues.

| R-4A s/n 3735: Front view with front panel removed. |

| R-4A s/n 3735: Chassis with preselector reduction drive, PTO & dial assembly, and old can capacitor removed. Notice corroded condition of chassis. |

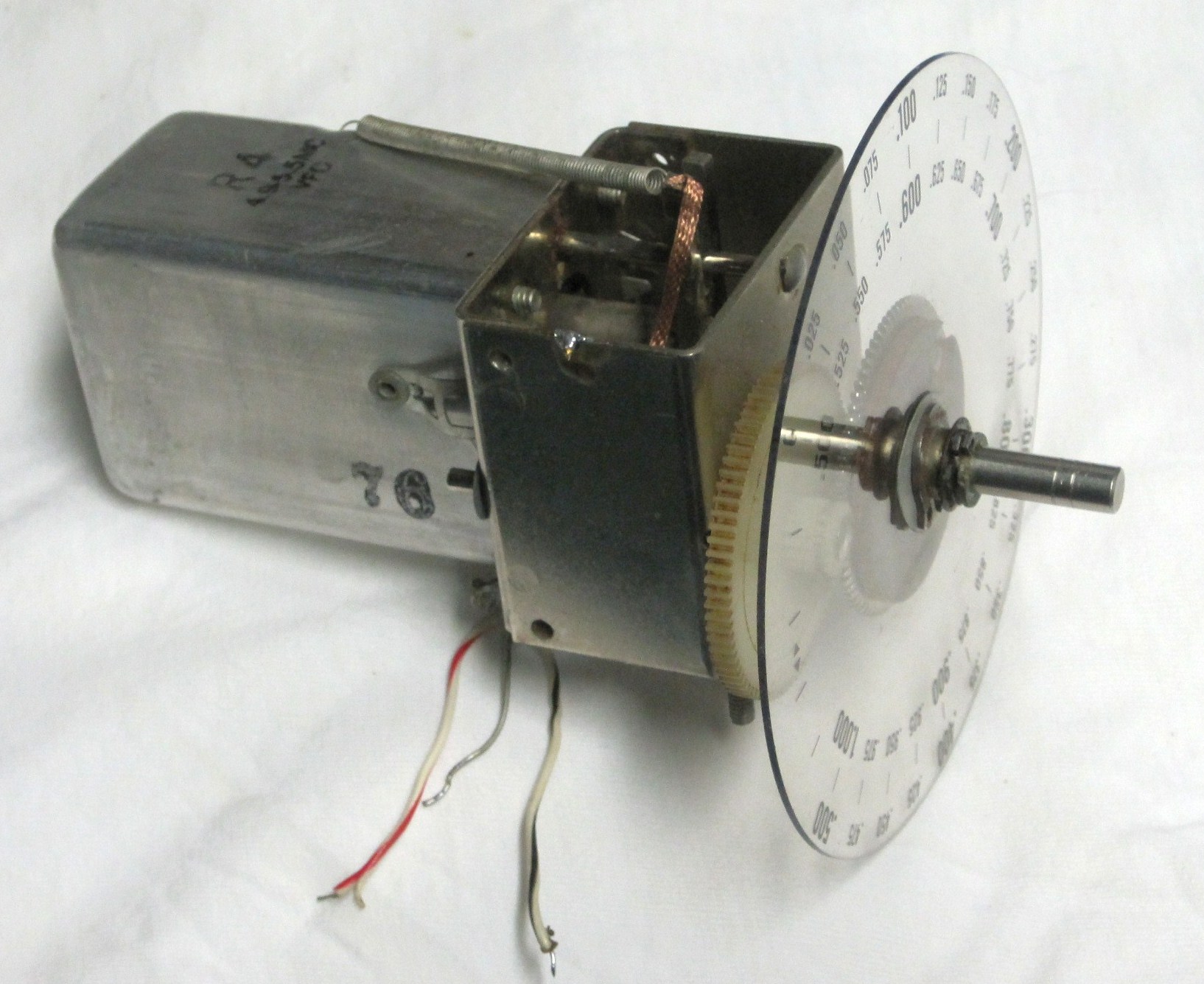

| Drake R-4A Preselector reduction drive. Just visible is a groove worn into the steel shaft by the ball bearings that causes slippage. A new shaft will be turned on a lathe to replace it. |

| Lots of parts to keep track of when a radio is disassembled! |

R-4A #3781: A decent, clean receiver with a copper chassis in generally very good shape, and in overall working condition with only one significant problem, i.e., instability in the Permeability-Tuned Oscillator (PTO). It had never been re-capped so after installing a re-cap kit and doing some switch & pot clean-up and a touch-up of the alignment, the only remaining problem was the PTO. |

| This is the PTO assembly removed from R-4A #3781 and replaced with the PTO from #3735. The two PTOs are identical. The factory-recommended "grounding braid" modification is visible. |

|

|

| R-4A s/n 5757G: It would be difficult to find an R-4A in nicer cosmetic condition than this one - but that doesn't mean it also works perfectly! |

R-4A s/n 5757G: The can capacitor on the right side of the receiver is the new "re-cap" unit. Note the faded color of the meter & dial faces (top photo on previous page); the translucent blue-green plastic strips over the dial lamps have not yet been replaced. |

3. MS-4 SPEAKER

Along the way during the R-4A accumulation odyssey I picked up a Drake MS-4 speaker in very nice condition. There were no problems with it but I did order a NOS Collins 5" x 7" speaker from Surplus Sales of Nebraska and replaced the original 5" x 7" unit, and it did improve the sound quality.

4. T-4X TRANSMITTER

All the while I was working on the three R-4As I was keeping my eyes open for a suitable companion transmitter and one was finally located. The T-4X I purchased dates to around early 1966 and, despite a few scratches on the cabinet, is a nice-looking unit. The original two-section "can" capacitor was still in place but only for looks as it is no longer connected, its two sections having been replaced with discrete electrolytic capacitors very neatly installed. While a "re-cap" can capacitor can be purchased the discrete replacements do the job so there is no reason to rush to change them. Switches had been cleaned by the previous owner, the PTO is stable and accurate, and no alignment has been attempted. The front panel was removed and washed. The transmitter included both the original manual and a clean, bound copy for everyday use.

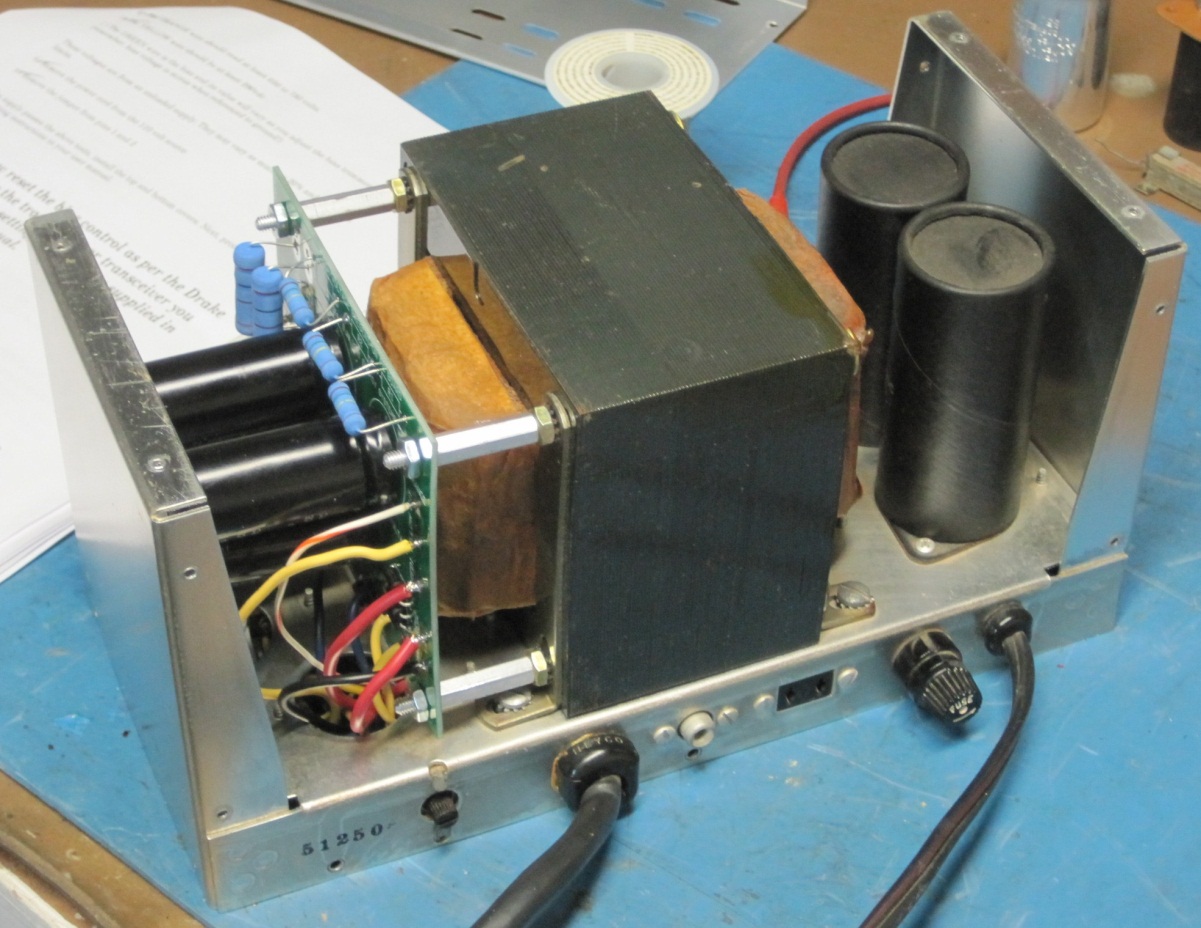

5. AC-4 POWER SUPPLY

The T-4X transmitter uses an external power supply, either a Model AC-3 (open-frame) or AC-4 (enclosed). I was fortunate enough to locate an AC-4 power supply, about 1975 vintage and in very nice condition, from an area ham in Stafford County. We arranged a face-to-face dinner meeting in Fredericksburg and I came home with the supply. Although the supply was in excellent shape and worked very well - allowing me to put the T-4X transmitter "on the air" for a few contacts - prudence dictated that I rebuild the supply using a modern upgrade kit to ensure longevity and protect the transmitter (sudden loss of the bias supply, for example, can cause failure of the final amplifier tubes in the T-4X). A kit was obtained, modifications were completed, and the AC-4 should be good for another 30 years.

|

|

6. ON-THE-AIR OPERATION & ADDITIONAL MODIFICATIONS

So far, R-4A #3781 and the T-4X have been used solely as separate transmitter & receiver and not in transceive mode, i.e., where either the receiver or the transmitter controls both units (the latter operation requires careful alignment of the units to ensure adequate LO injection and accurate tracking to minimize "chasing" another station across the band). T-4X power output is within specifications although I have kept it throttled back to about 60 watts to conserve the 6JB6 finals (which are becoming increasingly more expensive and hard to find); after all, I use this rig for fun, not for serious traffic work or DXing.

One issue with vintage tube equipment that sometimes needs to be addressed is heat and the Drake R-4A and T-4X are no exception. The earlier 13-tube R-4A power transformer gets VERY hot, almost too hot to touch, although the 11-tube version runs a bit cooler. Because I'm currently using a 13-tube version (#3781) in the shack I installed a 2.4", 12 VDC brushless fan on top of the receiver to draw hot air out and cool the transformer case. The fan is held in place by two screws protruding through the ventilation holes in the cabinet top with fiber washers above & below to prevent marring the paint. Since the T-4X has heat build-up in the PA compartment an identical fan was installed on the back of the transmitter PA cage to aid in keeping the final amplifier tubes cooler. It is held in place by screws protruding through holes in the PA section cover.

|

|

Both fans have 120 ohm, 5 watt dropping resistors installed in series with one of the fan leads to lower the operating voltage and the fan speed, a low speed being adequate for this application. The fans are powered by the station 13.6 VDC bus. (NOTE: The value of the dropping resistor was chosen empirically to keep the speed low while still ensuring reliable start-up when DC power is applied. The amount of resistance necessary will vary with the exact fan purchased.)

The complete shack at K4MSG, mid-November, 2010.

The Drake T-4X, R-4A and MS-4 have been integrated into a station that includes modern transceivers & accessories. This installation is configured to allow the operator to easily connect accessories (antennas, speaker & phones, and key) to the rig of choice. There is also enough width & height on the "Drake shelf" to replace the R-4A with the 2B and install a Drake 2NT CW transmitter (if available) in place of the T-4X.

PART III: PARTS & INFORMATION SOURCES

The following list should help with locating suitable parts for restoration of older vintage gear. Although keyed primarily to Drake equipment there are some suppliers who sell specific parts for other brands and/or generic components and these are noted.