Norm Styer, AI2C - Clarkes Gap, Virginia

Friday, May 9, 2008

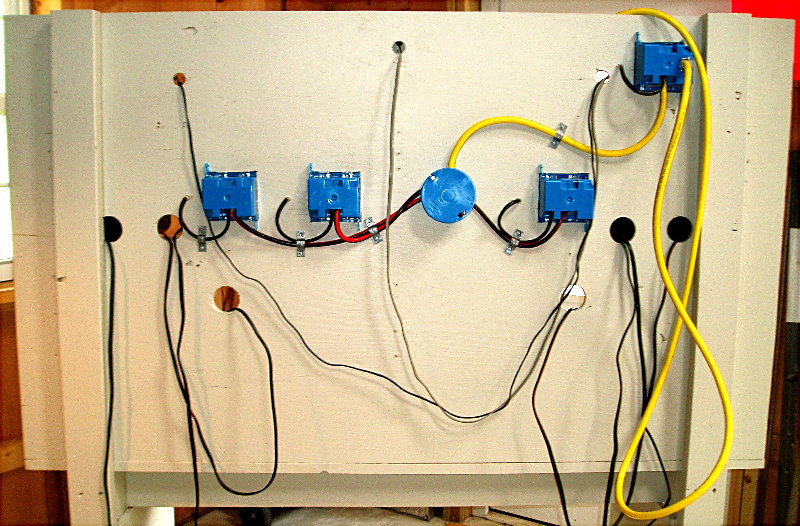

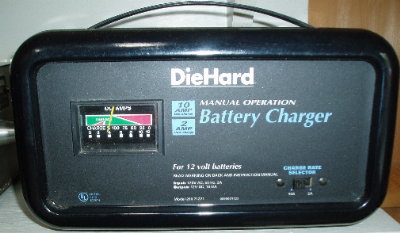

A little background. You never know when you have to roll. You always wonder whether those batteries still have a charge. Can I get 18-hours of station operations out of each of them? I try to keep at least one up just in case. But about this time each year, I try to hook them all up and decide whether they'll get me through another June Field Day. I have a bunch of batteries - some several years old - and a bunch of chargers. This stuff sorta sits around the barn. All this convinced me that I should try to organize all this.